Are you wanna custom paper bags that are the perfect size and shape for your needs? You want a bespoke finish that truly reflects your brand at the best price. So how do you know where to start? Canfei Packing have put together this complete guideline to Custom Luxury Paper Bags to help.

1. Choose the size of your paper bag

The base price of your packaging bag will depend on its size. Smaller bags are cheaper than larger bags, due to the quantity of materials used and shipping costs.

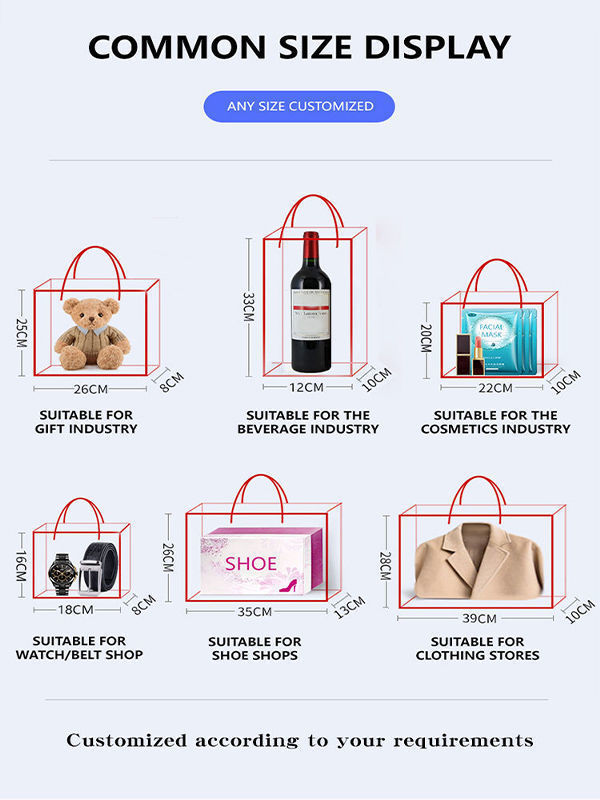

If you choose from our standard paper shopping bag sizes we can make up your order without making a new cutter, so ordering one of our standard sizes is cheaper.

Take a look at our Bag Size Chart to see our huge range of luxury bag sizes. If you need something different, we’re happy to make up bespoke bag sizes to order.

2. Decide how many paper bags to order

Our minimum order for luxury paper bags is 1000pcs bags. If you order more the price per bag will be lower, as bigger orders are more cost effective. Customers often place repeat orders having been so pleased with our printed paper bags – if you think this might be you then it is cheaper to place a larger order in the first place!

3. How many colors do you want to print?

The price of your paper bag will vary depending on how many colours you want to print, and whether you want a special option such as metallic colour print. A single colour print logo will cost less than a full colour printed logo.

If your logo or artwork has up to 4 colors we can print using either screen print or offset print technology, using the Pantone specific colors for your print.

For printing of more than 4 colors we offer full color print using high quality offset print technology using CMYK colour specification. If you need any assistance in understanding which is best for your printed bags please let us know.

Your bag will look and feel different depending what type of paper it is made from and how thick it is. The type and weight of paper used will also affect the strength and durability of the bag.

Here are the types of paper we use, and their thickness:

Brown or White Kraft Paper 120 – 220gsm

Uncoated paper with a natural feel, Kraft paper is the most popular and cost effective paper. You will most often see it used for printed paper bags with twisted paper handles or prestige kraft paper bags.

White, Brown or Coloured Recycled Paper 120 – 270gsm

Another uncoated paper with a natural feel, Recycled paper is made from 100% recycled old paper. No additional trees have been used to produce this paper so it is an eco-friendly choice. This paper can be widely used for production of all our bags.

Unocated Art Paper

Uncoated Art Paper is made from wood pulp. It is an ideal paper for making printed paper bags as it has a smooth surface that accepts prints well. It is available in different thickness, colours and textures to suit your needs:

- Uncoated Coloured Art Paper 120-300 gsm

Available in a wide range of colours, Uncoated Coloured Art Paper has depth and opacity. It provides a smooth surface for printing and is highly durable. Used mostly for our Unlaminated Paper Bags with a single colour screen print, or with extra finishes such as hot foil stamping and UV varnish.

- Coated White Card Paper 190-220 gsm

For this luxury paper the card paper base is covered with a thin mixture of mineral pigment and glue and smoothed with special rollers. The process gives Coated Card Paper a smooth feel and special opaque whiteness that means graphics printed on these bags will be more vivid, with clear and intense colours. This paper needs to be laminated after printing. Used for the Laminated Paper Bags in thickness between 190gsm and 220gsm.

4. Select the type of paper for your bags

6. Decide whether to have lamination

Lamination is the process of applying a thin layer of plastic to paper sheets to enhance and protect the printed content. Lamination finishes make the paper bag more tear-resistant, water-resistant and durable, so they can be handled more and are likely to be re-used. Canfei Packing don’t laminate bags made from uncoated paper, recycled paper or kraft paper.

Canfei Packaging have the following lamination options:

Gloss Lamination

This gives a glossy finish to your luxury paper bag, often making the print appear crisper and sharper. It provides a durable finish which resists dirt, dust and fingerprints.

Matt Lamination

Matt lamination gives an elegant and sophisticated finish. Unlike gloss lamination, matt lamination can provide a softer look. Matt lamination is not recommended for dark coloured bags as it is not scuff resistant.

Soft Touch Lamination / Satin Lamination

Soft touch lamination offers a protective finish with a matt effect and a soft, velvet-like texture. This distinctive finish encourages people to engage with the product as it is very tactile. Soft touch lamination resists fingerprints and is naturally more scuff resistant than standard forms of lamination. It is more expensive than standard gloss or matt lamination.

Metallic Lamination

For a reflective, bright finish we can apply metallised laminate film to your paper bags.

7. Add a special finish

For that extra flourish, add a special finish to your brand paper bag.

Inside Print

Spot UV Varnish

Embossing and Debossing

Hot Foil / Hot Stamping

Please send us size, order quantity, material/application scene to get instant quotation!

CALL US: +86-189-3803-5880

CALL US: +86-189-3803-5880

EMAIL: sophie@canfeicn.com

EMAIL: sophie@canfeicn.com

ADDRESS: No.1204 Xiashuijing Building No.250 Jihua Road Longgang District Shenzhen City Guangdong Province China

ADDRESS: No.1204 Xiashuijing Building No.250 Jihua Road Longgang District Shenzhen City Guangdong Province China

3 thoughts on “Complete Guide to Customized Paper Bags”